Austin Bergstrom International Airport (AUS)

Centralized Baggage Handling System Upgrades

LOD325 REVIT MODEL AT AUSTIN BERGSTROM INTERNATIONAL AIRPORT

OVERVIEW

This case study explores the project undertaken by Digital Building Services (DBS) at Austin Bergstrom International Airport (AUS) in 2020. The focus was on upgrading the Centralized Baggage Handling System. DBS played a crucial role as part of the Design/Build (D/B) team, leveraging advanced technology to improve the efficiency and effectiveness of the airport’s baggage handling system.

OUR PROCESS: REVIT MODEL CREATION FOR AUS

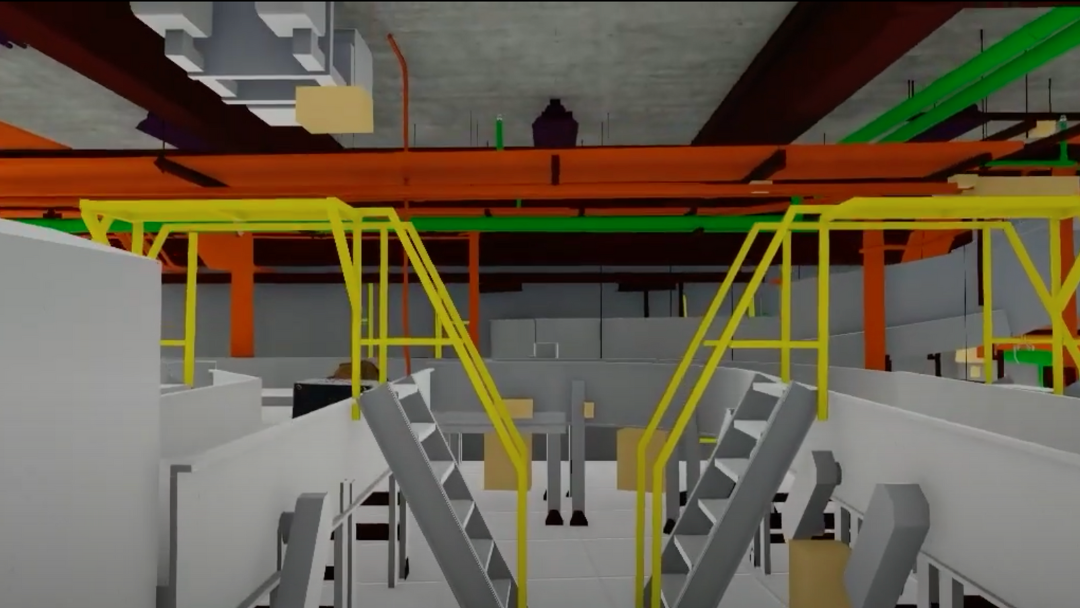

DBS was tasked with preparing a Level of Development (LOD) 325 Revit model. This model was critical for both design purposes and for aiding the General Contractor (GC) and their subcontractors in their Building Information Modeling (BIM) efforts.

The DBS team employed cutting-edge scanning technology to accurately capture the complex environment. This involved meticulous planning and execution to navigate the multi-level terminal space.

DBS’s role extended to encompass all Architectural, Structural, and Mechanical, Electrical, and Plumbing (MEP) components. This included both above and below the existing acoustical ceiling tile. The team ensured that all MEP components with a diameter of 25mm and above were included in the final model.

CHALLENGES

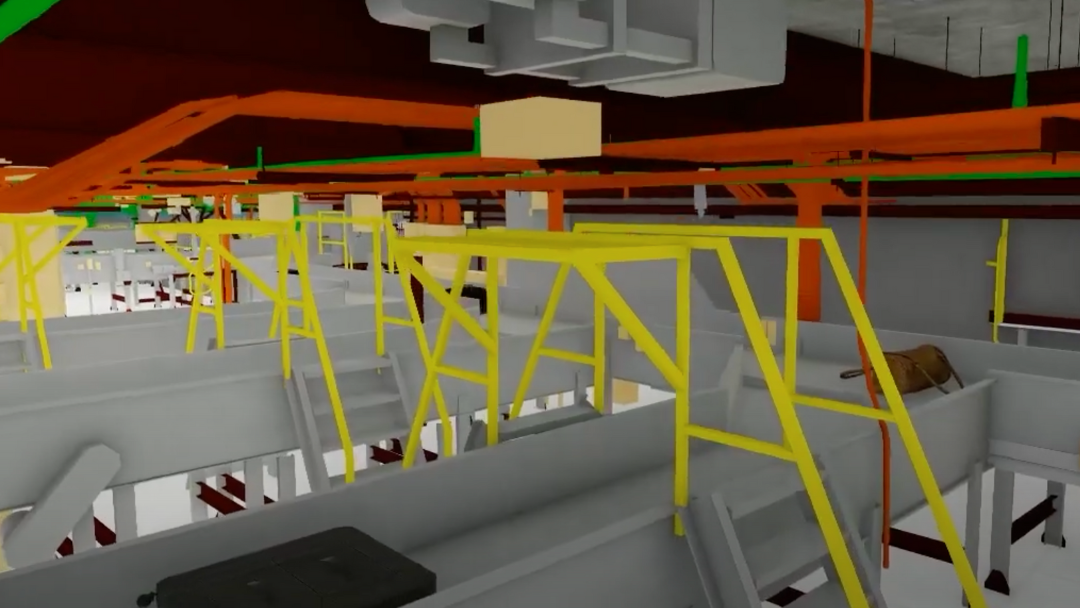

The project encompassed over 270,000 square feet of existing space across multiple levels of the terminal, presenting significant logistical and technical challenges.

BENEFITS

The successful completion of this project by DBS significantly enhanced the operational efficiency and reliability of the Centralized Baggage Handling System at Austin Bergstrom International Airport.

PROJECT RESULTS AT AUSTIN BERGSTROM INTERNATIONAL AIRPORT

Despite an accelerated project schedule, DBS successfully completed the fieldwork in just twelve calendar days. The model included an extensive area of 300,000 square feet, providing detailed insights into every aspect of the terminal’s existing structure and systems.

The use of the Revit model facilitated improved coordination among the D/B team, GC, and subcontractors. This collaborative approach was instrumental in navigating the project’s challenges.

This case study demonstrates DBS’s expertise in handling large-scale, complex projects with efficiency and precision, underscoring our value as a key player in the field of aviation 3D scanning.