Palm Beach International Airport

Baggage Handling System Improvements

BAGGAGE HANDLING SYSTEM IMPROVEMENTS

OVERVIEW

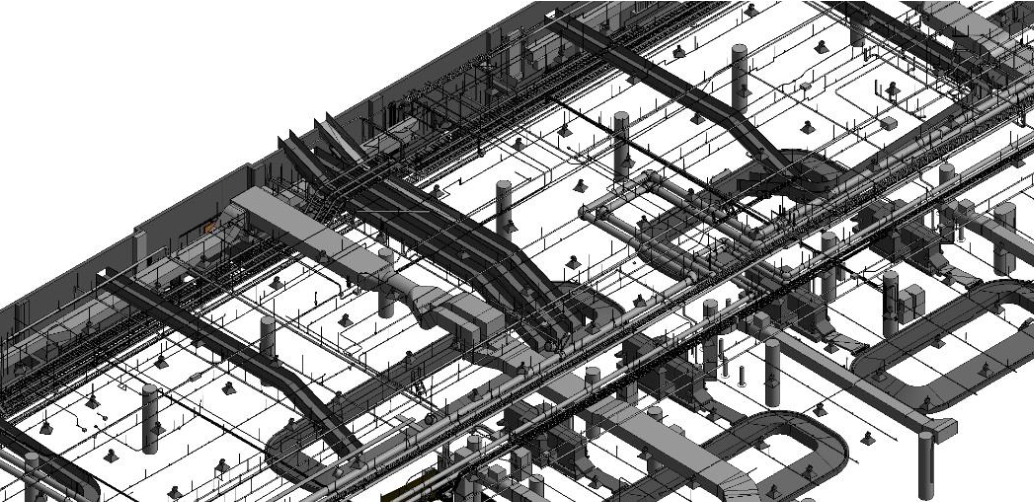

In a recent project, our team was tasked with digitally capturing and modeling a 75,000 square foot baggage handling facility for the Design/Build (D/B) team led by the General Contractor. The purpose was to provide an accurate representation of the existing facility to aid in future renovations, expansions, and maintenance. The scope of the model was comprehensive, encompassing not only the visible infrastructure but also the intricate interstitial spaces above the Baggage Handling System (BHS).

Our primary goal was to scan the current state of the BHS and generate a precise Revit model, thereby enabling our General Contractor (GC) client to streamline their Building Information Modeling (BIM) process.

CHALLENGES

Accessibility: Interstitial spaces, given their confined nature and the maze of utilities running through them, can be challenging to scan. Achieving a comprehensive scan in these areas requires careful planning and sometimes specialized equipment.

Data Overload: Capturing every detail down to components one inch in diameter can lead to an overwhelming amount of data, which requires robust processing power and specialized software to handle effectively.

BENEFITS

Precision Planning: With a detailed Revit model, the D/B team can plan renovations and expansions with a high degree of accuracy, reducing the chances of costly mistakes or oversights.

Cost Savings: An accurate model reduces the likelihood of encountering unforeseen challenges during the construction phase, leading to potential cost savings.

3D LASER SCANNING PROCESS

To begin with, a thorough 3D laser scanning of the entire facility was undertaken. This method was chosen for its precision and ability to capture detailed data in a non-intrusive manner, ensuring minimal disruption to the facility’s operations.

Every element of the facility was scanned, from the baggage conveyor systems to structural and architectural features.

Special attention was given to the Mechanical, Electrical, and Plumbing (MEP) components as well as fire protection systems, ensuring that every component one inch in diameter and larger was accurately captured.

Additionally, the interstitial spaces above the BHS, often overlooked in traditional surveys due to their complexity and accessibility challenges, were also scanned to provide a comprehensive model.

Once the scanning was completed, the data was processed and converted into a detailed Revit model. This model served as a digital twin of the facility, providing a 3D representation of every nook and cranny, from the major structural elements down to the smallest MEP component.

PROJECT RESULTS

The Revit model delivered to the D/B team proved invaluable. The General Contractor and their team were equipped with an accurate, detailed representation of the facility, eliminating guesswork and minimizing the potential for costly mistakes during subsequent design and construction phases.

The inclusion of the interstitial spaces in the model proved especially beneficial, as these areas often pose challenges in terms of access and accurate documentation. With the comprehensive model in hand, the D/B team was able to plan renovations more efficiently, ensure a more accurate budget, and foresee potential challenges before they became problematic.

In conclusion, this project highlighted the immense value of digital building services in modern construction and renovation. Through advanced scanning techniques and detailed Revit modeling, facilities can be understood and represented like never before, paving the way for efficient, informed, and innovative solutions.