BHS Improvements at LAX

3D Laser Scanning and Revit Model at Los Angeles International Airport

CREATING A PRECISE AS-BUILT CONDITION SCAN AND REVIT MODEL

OVERVIEW

Swinerton, a renowned General Contracting company, faced significant challenges with the baggage handling system at LAX.

Due to years of mechanical, electrical, and plumbing (MEP) modifications and other changes, existing as-built documentation was outdated and insufficient for effective Building Information Modeling (BIM) coordination.

Recognizing the complexity of the task, Swinerton enlisted Digital Building Services (DBS), known for its extensive experience in over sixty North American airport projects, to create an updated and precise as-built condition scan and Revit model.

The quality of the scan was fantastic, and we also had them generate a Revit model. I was impressed on the Revit model as well. They were very responsive and kept me in the loop for status of receiving models. I would hire them again.

PHASE ONE

INITIAL ASSESSMENT AND EVALUATION OF THE CURRENT MEP

The process undertaken by Digital Building Services (DBS) for Swinerton began with an initial assessment and planning phase, where DBS conducted a comprehensive evaluation of the baggage handling area.

This initial step was crucial for understanding the project’s scope and the specific challenges it presented, including the extensive mechanical, electrical, and plumbing (MEP) modifications and other changes that had occurred over the years. Following this evaluation, DBS worked closely with Swinerton and other project stakeholders to gather detailed requirements for the Revit model, ensuring clarity on the level of detail needed and identifying any areas of particular concern.

PHASE TWO

3D SCANNING AND MODELING

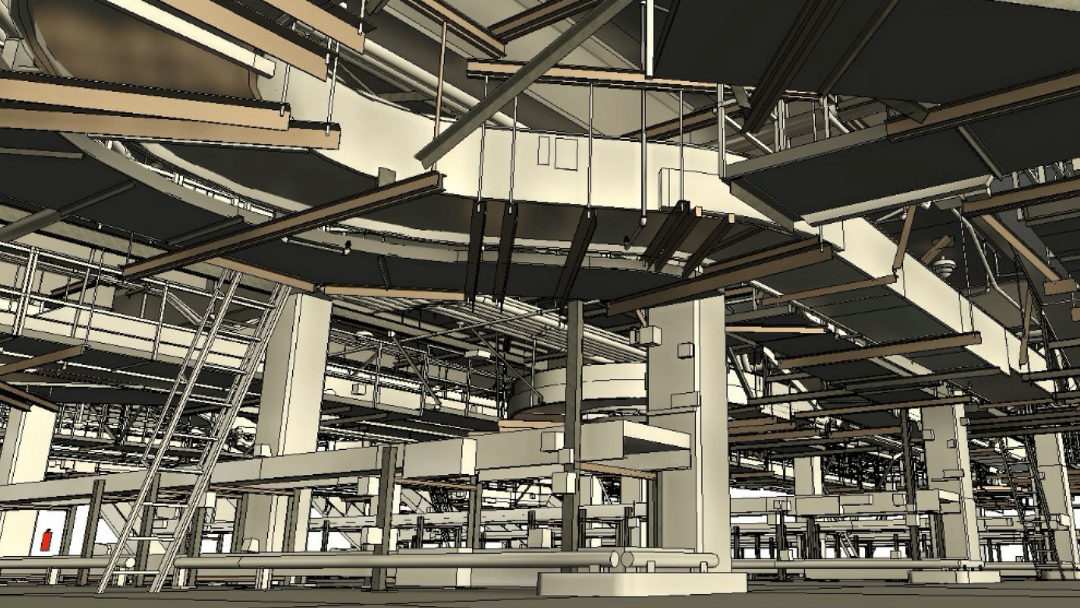

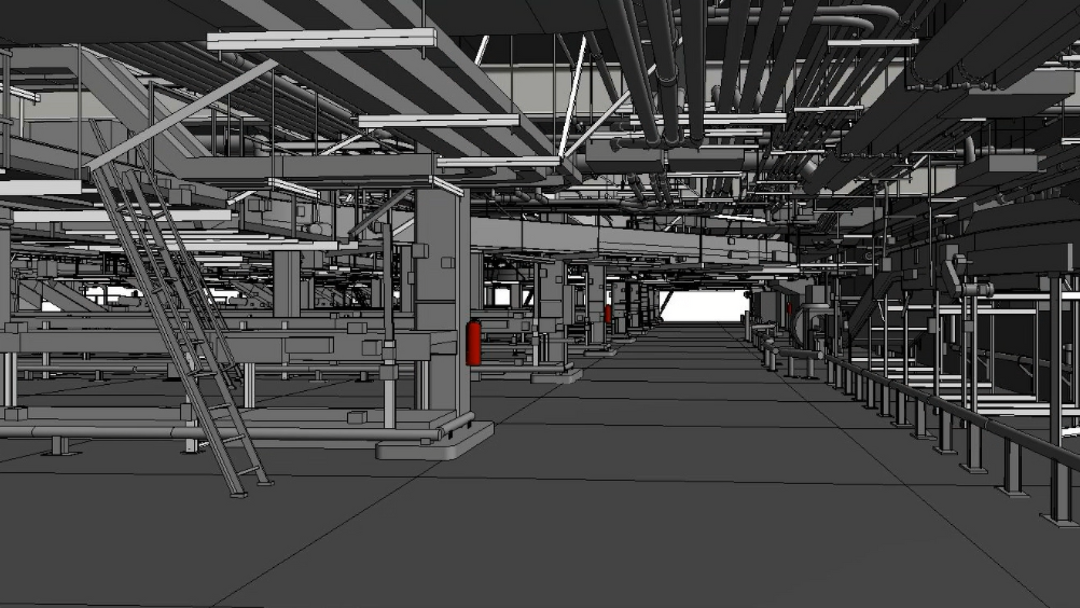

DBS employed advanced scanning technologies to capture the existing conditions of the baggage handling system with high precision.

This involved scanning the entire area to document every modification, no matter how minor, to create a comprehensive digital representation of the current state.

The use of our cutting-edge technology was pivotal in overcoming the challenge of outdated and insufficient as-built documentation, enabling DBS to produce an accurate and detailed dataset for the subsequent modeling process.

PHASE THREE

REVIT MODEL

With the scanning complete, DBS then proceeded to the modeling phase, leveraging our extensive experience in airport infrastructure projects to efficiently navigate the complexities of the baggage handling system.

The team utilized the data collected during the scanning phase to develop a detailed Revit model that incorporated all MEP modifications and other relevant changes. This model was constructed with a high degree of accuracy, ensuring it would serve as a reliable foundation for effective BIM coordination among all project stakeholders.

PROJECT RESULTS

Throughout the process, DBS maintained a collaborative approach, ensuring ongoing communication with Swinerton and other involved parties.

This facilitated the smooth integration of the Revit model into the broader project workflow, enabling stakeholders to plan and execute renovations more effectively.

The successful completion of this project not only addressed the immediate needs of Swinerton but also set a new standard for precision and efficiency in BIM coordination for airport infrastructure projects.