3D Laser Scanning in Texas – AUS Baggage Claim Upgrade. In 2020, Austin Bergstrom International Airport embarked on an ambitious project to upgrade its Centralized Baggage Handling System, enlisting the expertise of Digital Building Services (DBS). This project not only showcases the power of advanced digital modeling in large-scale infrastructure projects but also highlights the efficiency and innovation possible in the aviation industry.

Read more about our case study here.

The Challenge: A Complex, Multi-Level Upgrade

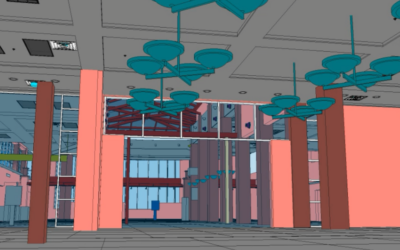

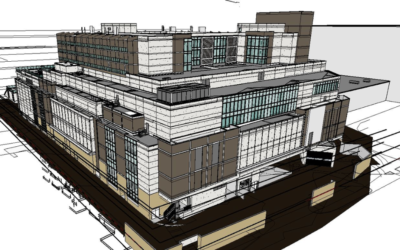

The primary challenge at AUS was upgrading the baggage handling system across an extensive area of 270,000 square feet, spanning multiple levels of the terminal. This task was daunting, given the intricacies of the existing structures and systems. DBS’s mission was to create a detailed Level of Development (LOD) 325 Revit model that would serve as a blueprint for design and construction efforts.

The Process: Advanced Technology and Expedited Execution

DBS employed state-of-the-art scanning technology to accurately map out the vast and complex terminal space. Their responsibilities were comprehensive, covering architectural, structural, and all Mechanical, Electrical, and Plumbing (MEP) components. Importantly, DBS included every MEP component with a diameter of 25mm and above in the final model, labeled using standard AIA Revit families for clarity.

Despite an accelerated schedule, DBS completed the fieldwork in a mere twelve days. This rapid execution was crucial in maintaining the project’s momentum and meeting tight deadlines.

The Results: On-Time Delivery and Enhanced Operational Efficiency

The most remarkable outcome of this project was the timely delivery of the LOD325 Revit model, despite the accelerated timeline and the project’s complexity. This model covered an even larger area than initially scoped, extending to 300,000 square feet.

The use of the Revit model fostered enhanced collaboration among the various teams involved, including the Design/Build team, the General Contractor, and their subcontractors. This collaborative environment was key to overcoming the project’s numerous challenges.

The precision and quality of the model played a pivotal role in the successful upgrade of the baggage handling system. It ensured that every detail was accounted for, leading to an improvement in the system’s efficiency and reliability.

3D Laser Scanning in Texas – Digital Building Services

The AUS baggage handling system upgrade is a testament to the possibilities when innovation meets expertise. DBS’s ability to handle such a large-scale and complex project with efficiency and precision is commendable. This case study not only highlights DBS’s prowess in digital building services but also serves as an inspiring example for future infrastructure projects in the aviation sector.

0 Comments